Profiting from waste isn’t about better recycling—it’s about redesigning your business to eliminate the concept of “waste” entirely.

- Map every output, tangible and intangible, to uncover its hidden asset value.

- Shift from selling products to selling services (PaaS) to retain material ownership and create recurring revenue.

Recommendation: Start by conducting a full-spectrum by-product audit to identify your most valuable, untapped resource stream.

For most small and medium-sized enterprises (SMEs), rising operational costs feel like an unstoppable force. Raw material prices are climbing, supply chains are fragile, and the line between profit and loss is thinner than ever. The conventional response is to tighten belts and manage expenses, with “waste management” often seen as just another costly line item. Business owners are told to recycle more, go paperless, or sell scrap for pennies on the dollar. But what if this entire perspective is flawed?

What if the piles of offcuts, the vented heat, the used packaging, and the obsolete equipment weren’t liabilities to be managed, but assets waiting to be monetized? The conversation is shifting away from simply reducing waste and toward a more radical, entrepreneurial approach: by-product valorization. This isn’t about being a better recycler; it’s about fundamentally re-architecting your business model to see every output as a potential input for a new revenue stream. It’s a strategic pivot from a linear “take-make-waste” system to a closed-loop, circular one where nothing is lost and everything has value.

This guide moves beyond the basics of waste disposal. We will explore the actionable strategies that allow an SME to not just survive but thrive by turning its operational “waste” into a source of economic resilience and innovation. We will deconstruct the methods for identifying these hidden assets, explore transformative business models, and provide a clear roadmap for building a more profitable and sustainable enterprise.

This article provides a strategic framework for this transformation. Below is a summary of the key areas we will explore, guiding you from understanding the economic imperative to implementing practical, profitable circular strategies in your own operations.

Summary: From Waste Streams to Value Chains

- Why Are Raw Material Costs Rising Faster Than Inflation?

- How to Map Your Company’s Waste to Find Hidden Gold?

- Selling Light vs Selling Bulbs: Which Model Is More Resilient?

- The Marketing Mistake That Gets Brands Sued for Greenwashing

- How to Design Products That Can Be Repaired in 5 Minutes?

- The Fatal Mistake of Over-Engineering Sustainable Products

- How to Repurpose Old Car Batteries for Home Solar Storage?

- How Can Companies Operate Within Planetary Boundaries?

Why Are Raw Material Costs Rising Faster Than Inflation?

The traditional linear economic model—extract resources, manufacture products, sell them, and forget them—is showing its age. For decades, it powered growth, but today it exposes businesses to severe volatility. Geopolitical instability, strained logistics, and increasing competition for finite resources mean that the price of everything from timber to cobalt can spike without warning. This isn’t just a temporary disruption; it’s the new reality of a resource-constrained world. In fact, projections show that without urgent action, resource extraction could rise by 60% by 2060, putting even more pressure on prices.

For an SME, this dependency on virgin materials is a critical vulnerability. Your business is at the mercy of global market forces far outside your control. A circular business model acts as a powerful hedge against this uncertainty. By designing systems to recover, reuse, and remanufacture your own by-products or those from other industries—a concept known as industrial symbiosis—you decouple your growth from the volatile commodity markets. You are no longer just a consumer of raw materials; you become a producer of them.

This shift transforms a cost center (waste disposal) into a revenue driver and a strategic buffer. Instead of paying to have materials hauled away, you are creating a secure, localized supply chain for your next product cycle or selling those materials to another business that sees their value. This is the foundational economic argument for the circular economy: it’s not just an environmental ideal, but a pragmatic strategy for building long-term business resilience in an increasingly unpredictable world.

How to Map Your Company’s Waste to Find Hidden Gold?

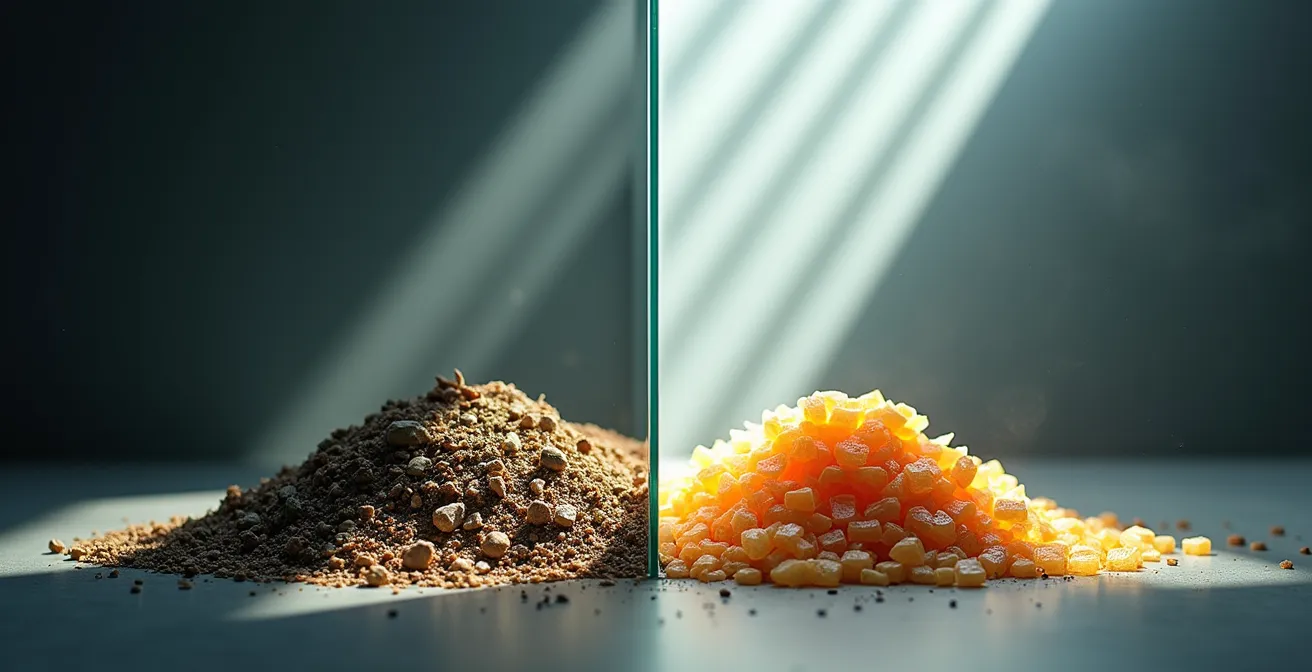

You can’t profit from what you don’t measure. The first and most critical step in by-product valorization is to conduct a comprehensive audit of every output your business generates. This goes far beyond the dumpster. It’s an investigative process to map all the “waste” you produce, both tangible and intangible. This includes everything from metal offcuts and sawdust to excess heat from machinery, unused server capacity, and even employee downtime between tasks. The goal is to create a detailed map of your company’s metabolic flows to identify where value is leaking out.

This process, often called waste stream mapping, involves several key stages. You begin with a physical audit to categorize and quantify the types of solid waste you generate. But the real “gold” is often found in the less obvious streams. Are you venting heat that could be captured to warm your office or pre-heat water? Is your delivery truck returning empty when it could be carrying another local company’s materials for a fee? This is where technology like IoT sensors can provide real-time data on everything from equipment efficiency to material flow, revealing patterns and inefficiencies that are invisible to the naked eye.

Once you have this data, you can calculate the embedded value—the raw material cost, energy, and labor—in each waste stream. This allows you to prioritize. A small stream of a high-value material like copper might be more profitable to capture than a large stream of mixed, low-value plastic. This strategic audit transforms your perception: “waste” is no longer a homogenous problem but a diverse portfolio of potential assets.

As this visualization suggests, a structured map of your outputs brings clarity and reveals opportunities. Each sorted pile represents not a disposal cost, but a potential product. The key is to shift your mindset from waste management to resource archaeology—digging into your own processes to unearth value that others have overlooked.

Your Action Plan: The By-Product Audit Checklist

- Points of Contact: List all channels and processes where by-products are generated (e.g., production lines, packaging stations, energy systems, logistics).

- Collect Data: Inventory existing outputs by type, volume, and frequency. Include tangible (offcuts, packaging) and intangible (waste heat, server downtime) resources.

- Analyze for Coherence: Compare your list of by-products against your company’s core mission. Where is there a clear mismatch between what you value and what you discard?

- Assess Value & Opportunity: For each stream, evaluate its potential for internal reuse, local sale (industrial symbiosis), or transformation into a new product. Create a simple grid rating each by-product on “ease of capture” vs. “potential value.”

- Create an Integration Plan: Identify the top 1-3 opportunities and create a pilot project to capture and valorize that stream. Prioritize “quick wins” to build momentum.

Selling Light vs Selling Bulbs: Which Model Is More Resilient?

Once you’ve mapped your resources, the next question is strategic: how do you structure your business to capitalize on them? One of the most powerful shifts in the circular economy is the move from selling products to selling services. This is the essence of the Product-as-a-Service (PaaS) model. The classic example is “selling light, not lightbulbs.” Instead of selling a physical bulb, a company sells a subscription to guaranteed illumination. The company retains ownership of the bulb, is responsible for its maintenance and replacement, and, crucially, its end-of-life recovery.

This simple change has profound implications. When you sell a product, your incentive is for it to have a limited lifespan so the customer has to buy another one. When you sell a service, your incentive is the exact opposite: you want that product to be as durable, efficient, and easy to repair as possible, because every failure costs you money. This aligns your profitability directly with resource efficiency and sustainability. You are no longer in the business of transactions; you are in the business of performance and relationships.

For an SME, this model creates predictable, recurring revenue streams instead of volatile, one-off sales. It also builds incredible customer loyalty, as you become an integrated partner in their success. Most importantly, it internalizes the “waste” problem. Since you own the asset, you are incentivized to design it for disassembly, repair, and remanufacturing, turning its components into the raw materials for your next service contract.

The contrast between these two approaches is stark, affecting everything from cash flow to customer relationships. As a comparative analysis from the Ellen MacArthur Foundation shows, the PaaS model is inherently more resilient.

| Aspect | Traditional Product Sales | Product-as-a-Service (PaaS) |

|---|---|---|

| Revenue Model | One-time purchase | Recurring subscription |

| Material Ownership | Transfers to customer | Retained by provider |

| End-of-Life Recovery | Uncertain/customer dependent | Contractually guaranteed return |

| Cash Flow | Volatile, transaction-based | Predictable, recurring |

| Customer Relationship | Transactional | Ongoing partnership |

The Marketing Mistake That Gets Brands Sued for Greenwashing

As you transition to a more circular model, the temptation to shout your green credentials from the rooftops is strong. But this is where many well-intentioned companies make a critical error. Vague, unsubstantiated claims like “eco-friendly,” “sustainable,” or “green” are not only meaningless to savvy consumers, but they can also land your business in legal trouble for greenwashing. The fatal marketing mistake is focusing on broad, emotional sustainability claims instead of specific, verifiable data about resourcefulness.

Authentic circular marketing isn’t about claiming you’re “saving the planet.” It’s about transparently showing how you’ve engineered a smarter, more efficient business. Instead of saying “our product is sustainable,” say “our product uses 40% fewer virgin materials by incorporating our own manufacturing by-products.” Instead of “we’re a green company,” show “we reduced our waste-to-landfill by 75% last year, and here’s the data.” This approach, grounded in what the U.S. Environmental Protection Agency calls a circular economy, builds trust and credibility.

Your marketing should be framed around innovation and resourcefulness, not just environmentalism. You are not just being “good”; you are being smart. This resonates far more with customers and B2B partners. The key is radical transparency. Document your processes, publish your metrics, and be honest about your journey, including the challenges. Third-party certifications can be valuable, but only if they add a layer of verifiable proof, not as a substitute for your own transparent data.

Think of your communication strategy like this visual: a clear, transparent view into your transformation process. The story isn’t just the beautiful finished product; it’s the intelligent, documented journey from “waste” to wealth. This is what builds an unshakeable brand reputation and protects you from the ever-growing legal and reputational risks of greenwashing.

How to Design Products That Can Be Repaired in 5 Minutes?

A truly circular model cannot exist without products designed for it. If a product is glued together and impossible to take apart without breaking it, its potential for reuse, repair, or remanufacturing is zero. This is where Design for Disassembly (DfD) becomes a cornerstone of profitable circularity. The goal is to create products that can be easily and quickly taken apart using common tools, allowing for simple repairs, upgrades, and component harvesting at the end of life.

This approach directly combats the growing problem of waste, particularly electronic waste. In 2022 alone, a historic high of 62 million metric tons of e-waste was generated worldwide, much of it because products were not designed to be repaired. By contrast, a modular design using screws instead of glue, standardized components, and providing accessible repair guides turns a liability into multiple opportunities. You create new revenue streams from spare parts sales, build intense customer loyalty, and extend the life of your materials, reducing your reliance on new resources.

The key principles include using fewer material types, avoiding toxic adhesives, and making critical components like batteries and screens easily accessible. It’s a shift from designing for aesthetics or low assembly cost to designing for the product’s entire lifecycle.

Case Study: Fairphone’s Modular Revolution

Fairphone, a social enterprise based in the Netherlands, exemplifies the power of modular design. Their smartphones are engineered from the ground up to be repaired by the user. Components like the battery, camera, and screen are sold as individual modules that can be swapped out in minutes with a simple screwdriver. This not only dramatically extends the phone’s lifespan but also turns repair into a core part of their business model. By empowering users to upgrade and maintain their own devices, Fairphone builds a powerful community and demonstrates that profitability and repairability can go hand in hand.

The Fatal Mistake of Over-Engineering Sustainable Products

In the pursuit of circularity, there’s a dangerous trap: perfectionism. Many businesses over-engineer their products for an idealized version of recycling that doesn’t exist in the real world. They might spend a fortune developing a product made from a unique, 100% pure bioplastic that can only be recycled in a specialized facility that is three countries away. While theoretically “perfect,” this product is practically unrecyclable for the vast majority of users and infrastructure. This is the fatal mistake: prioritizing theoretical purity over pragmatic profitability.

A more robust and profitable approach is to design for the infrastructure that actually exists. This might mean accepting that “downcycling”—turning a material into a lower-grade product—is a far better outcome than no cycling at all. It means prioritizing mechanical separation (which is cheap and widely available) over complex chemical recycling (which is expensive and rare). For example, using a single type of plastic (monomaterial design) that is easily recycled everywhere is infinitely better than using a novel composite material that is theoretically superior but practically a contaminant in most recycling streams.

The goal is not to create the most technically perfect sustainable product in a lab, but to create a product that can be profitably recovered and reused in the messy reality of the current market. This involves making pragmatic choices: using screws instead of permanent adhesives, designing for easy separation of different materials, and focusing on robust, simple materials and processes. The most sustainable product is one that actually gets recycled, and that requires designing for economic viability, not just environmental purity.

How to Repurpose Old Car Batteries for Home Solar Storage?

Some of the most valuable by-products are also the most challenging to handle. A prime example is the growing stream of used lithium-ion batteries from electric vehicles (EVs). While often considered hazardous waste, these batteries represent a massive opportunity for by-product valorization. An EV battery is typically retired when it falls to about 70-80% of its original capacity—still far too valuable to be shredded. This is where “second-life” applications create an entirely new market.

Businesses are emerging that source these used batteries, test them to certify their remaining capacity and safety, and then repackage them into stationary energy storage systems for homes and businesses. These second-life batteries can be paired with solar panels to store excess energy, providing backup power and reducing reliance on the grid. This is a perfect example of cascading use: moving a product from a high-performance application (powering a car) to a less-demanding one (stationary storage), dramatically extending its useful life before it needs to be recycled.

The business model itself is often circular. Instead of selling the battery system, a company can offer “Battery-as-a-Service,” leasing the storage capacity for a monthly fee. This creates a predictable revenue stream and ensures the company retains ownership, allowing them to manage the battery’s eventual end-of-life recycling and recover the valuable metals within, like lithium and cobalt, for the next generation of products.

Case Study: Resource E-Waste Solutions’ Closed-Loop Battery Model

Resource E-Waste Solutions showcases a scalable Battery-as-a-Service model for lithium batteries from EVs and electronics. They manage the entire lifecycle, from safe sourcing and testing to disassembly and metal recovery. By leasing energy storage capacity to customers instead of selling hardware, they create a fully closed-loop system. This model not only extracts maximum value from the “waste” stream but also provides a vital service, demonstrating how complex industrial by-products can become the foundation of an innovative and profitable service business.

Key Takeaways

- The linear “take-make-waste” model is increasingly volatile; a circular model builds economic resilience.

- True profitability comes from designing business models (like PaaS) and products (for disassembly) that treat by-products as assets.

- Authentic marketing based on transparent data about resourcefulness is essential to avoid the greenwashing trap and build trust.

How Can Companies Operate Within Planetary Boundaries?

Ultimately, the transition to a circular economy is more than just a business strategy; it’s a necessary evolution to align economic activity with the planet’s finite resources. Operating “within planetary boundaries” means recognizing that natural systems have limits and designing economic models that thrive without exceeding them. For an SME, this might sound like an abstract global goal, but the principles of circularity are the practical tools to achieve it at a business level. Every decision to reuse a by-product, extend a product’s life, or shift to a service model is a concrete step toward this larger goal.

As the United Nations Environment Programme (UNEP) states, this approach creates a powerful alignment between business success and environmental stewardship. It’s a framework for a more resilient and equitable form of capitalism.

Three circular economy principles – eliminating waste and pollution, circulating products and materials, and regenerating nature – are win-wins for governments and enterprises, for more jobs and extended markets, enabling growth to improve lives but with less resource use and environmental impact.

– United Nations Environment Programme, From Waste to Wealth Statement

This is not about sacrificing profit for the planet. As we’ve explored, circular strategies directly enhance profitability by reducing costs, creating new revenue streams, and building stronger customer relationships. It’s about decoupling economic growth from resource extraction and waste generation. The final verdict on the linear versus circular model is clear when you compare their systemic impacts, as detailed in scientific analyses of their economic and environmental footprints.

| Metric | Linear Economy | Circular Economy |

|---|---|---|

| Resource Use | Take-Make-Waste | Reduce-Reuse-Recycle |

| Economic Model | Extractive | Regenerative |

| Waste Generation | 80-120B USD plastic waste/year | Waste as resource input |

| Job Creation | Limited to extraction | 6 million new jobs potential |

| Environmental Impact | 50% of GHG from extraction | Decoupled from growth |

By adopting a circular mindset, your SME is not just optimizing its own balance sheet; it is becoming an active participant in building a more durable and prosperous economic future for everyone.

The transition to a circular business model is no longer a niche interest but a core strategic imperative. The tools and models exist. Start today by conducting your first by-product audit and begin the journey of transforming your business from a consumer of resources into a generator of value.